3 Long-term cost impact

Environmental impact of €100 billion in arms investments

[back to table of content]

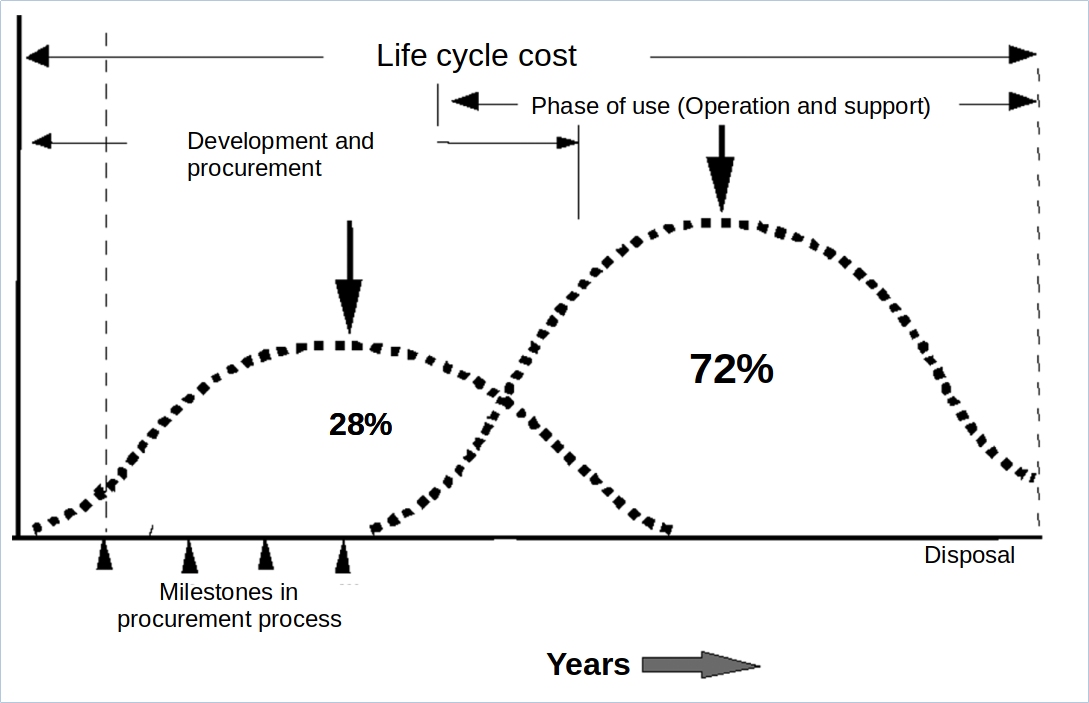

3.1 Life cycle cost

| Fig. 3-1: LCC structure of defence equipment The chart illustrates that most costs for defence equipment are incurred in the use phase. The milestones in the procurement process mark decision-making processes that largely fix the final costs of a defence equipment. It is also important to note: especially in the case of defence equipment, there are large temporal overlaps between the individual phases, which also stands in the way of cost transparency. Source of the graphic: Defense System Management College (1997)1Zitiert nach: Navarro-Galera u.a.: The Application of Life Cycle Costing in Evaluating Military Investments – aus: Defence and Peace Economics 2010 |

Basics

Most of the costs of buildings, infrastructure and mobile equipment arise in the use phase. Added to this are the not inconsiderable costs for disposal and, if possible, recycling at the „end of life“.2The problem that exists here can best be illustrated with printers, which is familiar to every PC user. While the purchase of an inkjet printer is very inexpensive, high costs can arise for the ongoing replacement of ink cartridges. But even with laser printers, the cost of toner cartridges far exceeds the relatively inexpensive purchase cost of the basically durable device, despite the more favourable LCC structure.

With the purchase of a device, due to its function, special operating materials and wear parts that need to be replaced may also have to be purchased regularly by the user. This creates customer loyalty, of which the manufacturers are of course aware. This means that they have a strategic interest in keeping the purchase price relatively low, with profitable calculation of the resulting follow-up business. This is especially true if there are no alternatives to the manufacturer’s offers for consumables and replacement materials, or if the customer is deterred from buying cheaper spare and replacement parts on the market with reference to warranty problems. 3In economics and especially in marketing, this is also called the lock-in effect.

This problem was first recognised by the US military in the early 1960s. The starting point was that relatively long service lives of 25 to 40 years are common for large military equipment. This led to the first considerations under the term Life Cycle Costs (LCC).

By the mid-1970s, procedures based on this were established in military procurement, also with specifications for industry.4According to MOD Australia (1998), https://www.anao.gov.au/work/performance-audit/life-cycle-costing-department-defence.

It is also important to note that once the development of a major piece of equipment is complete, 90% of the costs incurred in the use phase are also fixed. For example, the costs of fuel consumption, of course, depend on the actual use, but the specific costs per operating hour and/or route kilometre can hardly be changed.

In civilian areas, too, such considerations have been an established standard for decades. The cost factors for complex large-scale equipment and associated infrastructure in the utilisation phase are:

- Operating costs due to fuels and electrical power

- external services for the operational management of technical facilities

- Maintenance: inspections, servicing and repairs or overhauls.

- Changes of use and resulting conversions

- Modernisation through replacement of essential technical components

In the USA, it was derived from this that in the case of defence expenditures, these utilisation costs can be roughly estimated at 75% of the total costs in the life cycle.

|

Phase |

Infrastrukt. |

Schiffsbau |

Landfahrz. |

Starr |

|---|---|---|---|---|

|

Forschung & |

5% |

5% |

5% |

20% |

|

Investition & |

20% |

30% |

40% |

40% |

|

Wartung, Betrieb, |

75% |

65% |

55% |

40% |

|

Tab. 3-1: Percentage distribution of costs over the product lifetime |

||||

However, the LCC methodology is mostly limited to „internal“ costs for the respective users. In addition, there are usually further „external“ costs incurred by the general public, i.e. the state structures and other public service institutions. In principle, these are difficult to estimate.

The term Life Cycle Assessment (LCA) has become established for the consideration of ecological criteria in procurement processes, which is dealt with in Chapter 5.

Example car costs

This has been extensively studied and can be clearly illustrated in the case of private motorised transport, where considerable social costs are incurred through the consumption of resources, as well as burdens on the environment and human health.

In a study published at the end of 2021, „The lifetime cost of driving a car“6Gössling, Kees, Litman, 2022 https://www.sciencedirect.com/science/article/pii/S0921800921003943 with the already mentioned LCC methodology, exemplary calculations were made with three car models and a total of 33 individual factors:

- The private costs of ongoing operation are higher than the acquisition costs by a factor of 2 to 3.

- The societal costs due to environmental and health impacts as well as infrastructure resources used are to be estimated by a factor of 1.5 to 2 in addition to the private costs.

|

Kosten in Eur / Jahr |

Klein- |

Kompakt-wagen |

SUV |

|

Anschaffungspreis |

2.160 |

3.108 |

7.080 |

|

Summe interner Kosten |

6.703 |

7.657 |

12.899 |

|

Summe externer Kosten |

4.674 |

4.755 |

5.273 |

|

Gesamtkosten LCC |

11.378 |

12.412 |

18.171 |

|

Anteil Anschaffung von |

32% |

41% |

55% |

|

Anteil Anschaffung von Gesamtkosten |

19% |

25% |

39% |

|

Tab. 3-2: Life cycle costs using the example of passenger cars 7German passenger cars with Opel Corsa, VW Golf and Mercedes GLC were taken as a basis. The following parameters were taken as a basis: 15,000 km p.a. and car use by the owners over 50 years, |

|||

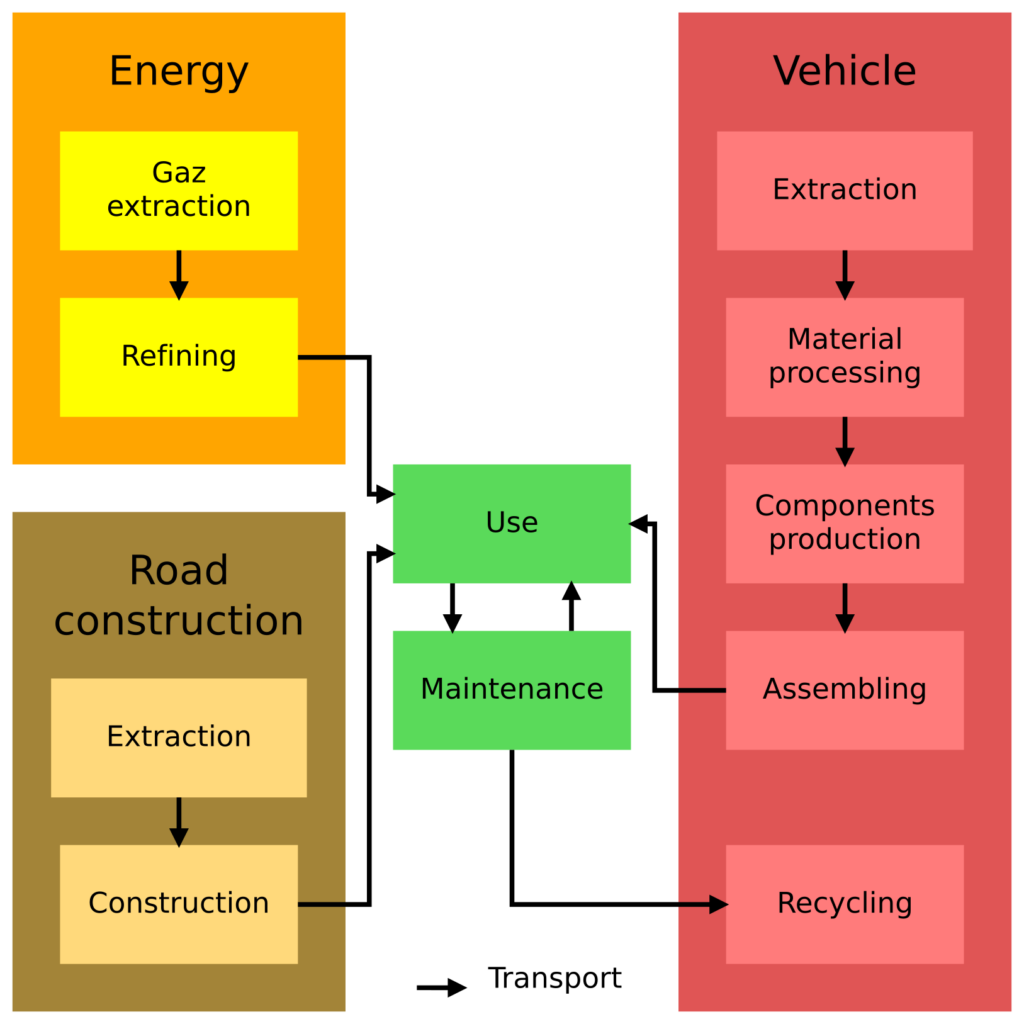

| Fig. 3-2: LCC structure in road transport (Graphic: Wikipedia) In addition to personal costs (vehicle + energy), the diagram also includes the use of the road system (road construction) as external costs. However, the latter are not completely covered. In addition, there would be health costs after traffic accidents as well as further health burdens due to traffic noise and air pollutants, which can only be roughly estimated. Even without these necessary additions, the original LCC concept is expanded to include external costs, as it is also the starting point of the LCA concept presented in Chapter 5. |

Procurements by the German Armed Forces

The Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) is administratively responsible for military procurement on the part of the BMVg.8https://de.wikipedia.org/wiki/Bundesamt_f%C3%BCr_Ausr%C3%BCstung,_Informationstechnik_und_Nutzung_der_Bundeswehr

The BAAINBw has end-to-end responsibility for the entire life cycle of defence equipment.9The inefficiency and „waste rate“ of this authority will not be discussed in detail here. See Brzoska, 2022 and Annex A.6 on the sustainability criterion of efficiency. Conceptually, this is based on a standardised procedure known as Customer Product Management (CPM), which has been developed and updated since 2001.10https://de.wikipedia.org/wiki/Customer_Product_Management.

In addition, this is defined via the Central Service Regulation A-1510/1 „Life Cycle Cost Management in the Bundeswehr across all CPM phases Life Cycle Cost Management (LCCM)“.

Customer Product Management (CPM) is implemented in the Bundeswehr, which includes cost recording in the life cycle.11https://www.bundeswehr.de/de/organisation/ausruestung-baainbw/ruestungsprojekte/customer-product-management

Life cycle costs are also addressed by the NATO Support and Procurement Agency (NSPA).12https://www.nspa.nato.int/about/life-cycle-management According to its own information, the Life Cycle Management Business Unit is in charge of 90 weapon systems and 170 projects.

Although LCC methods have been formally introduced in the Bundeswehr, their practical relevance is not tangible. In 2009, for example, the Federal Court of Audit (BRH) complained that the Bundeswehr was using a software-based procedure called „Logistic Support Analysis (LSA)“ to „minimise the life cycle costs of an armament product in particular“, but could not prove any monetary benefit.

This was also confirmed again in 2019 in response to a small question in the Bundestag on „Life cycle costs of defence equipment“.13https://dserver.bundestag.de/btd/19/151/1915104.pdf (The submission to this question at the time was prepared by the author). Although these costs were recorded for 90 projects, the „monetary benefit … could not be directly quantified“. cannot be directly quantified“. This statement is correct in that analysis tools cannot provide a defined benefit because different insights into possible cost drivers are gained in each project-specific individual case. Cost savings can therefore only be achieved with analysis tools on a project-specific basis, which then document their benefits via „success stories“. Otherwise, however, such a system can degenerate into a mere bookkeeping system, often referred to as a „data graveyard“. This means that a large data input is only matched by a small output for qualified management decisions.

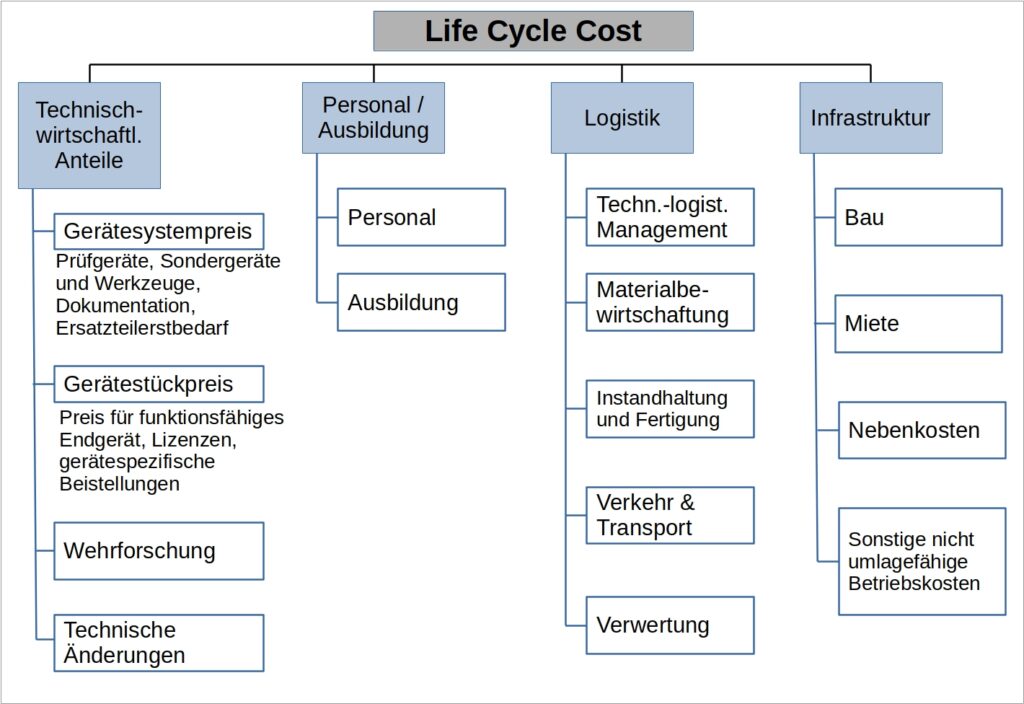

| Fig. 3-3: LCC structure in the Bundeswehr

The presentation corresponds to the structure introduced by the US military and the BMVg. Source: ZDV of the Bundeswehr |

Environmental aspects in the procurement process

Along with the law and the associated amendment to the Basic Law on the Special Fund, a law was passed to accelerate procurement measures for the Bundeswehr.15https://dserver.bundestag.de/btd/20/023/2002353.pdf Although the explanatory memorandum to the text of the law states in section VI.2. sustainability aspects:

„In view of the challenges of climate change, environmental award criteria should also play an increasing role in defence and security-specific contracts. This should create green lead markets also for a sustainable defence industry.“

It remains unclear, however, how this is to be practically incorporated into the procurement process. It is also confusing that the passage quoted above with similar content is already present in the general part of the explanatory memorandum in a similar form. There it additionally states:

„The Federal Government will also further strengthen the environmental aspects in procurement procedures, in particular to take into account CO2 emissions and other climate costs, already from its mandate under the Federal Climate Protection Act as a whole and also for the defence and security sector in particular.“

In the Federal Climate Protection Act mentioned here, however, the BMVg is not addressed at all, which will be discussed in more detail in Chapter 5 of this study.

This passage in the law is particularly questionable, however, because the consideration of environmental concerns in many cases requires a time-intensive bid review, which, however, is contrary to the intention of the acceleration procedure. It thus remains open to what extent the existing service regulations, which require environmentally sustainable procurement, are affected by this.

Material readiness of the Bundeswehr

According to the Agenda Rüstung of the BMVg16https://www.bmvg.de/de/themen/ruestung/ruestungsmanagement/ruestungsbericht adopted in autumn 2014 . Quote: The report … is divided into an „open“ Part 1 and a „classified for official use only“ Part 2. The classified Part 2 takes into account the special information needs of the parliament and, in doing so, takes into account the worthiness of protection of specific information of the defence sector. Note: The reports on material readiness were published at the same time as the armament reports until 2021, but this has no longer been the case since the 15th armament report in June 2022. [Since then, a „Report on the Material Readiness of the Bundeswehr’s Main Weapon Systems“ has been submitted twice a year. In the last report (II/2021), too, the Inspector General of the Bundeswehr complains about a too low available inventory of about one third of the 71 main weapon systems dealt with in the report. Apparently, however, a continuation of this reporting in the previous form (as a partial publication) is no longer intended. To what extent the procurement of ammunition is due to a planned training operation or as a stockpile for the event of war is difficult to determine. However, an estimate by a military expert on the war in Ukraine, who speaks of up to 20,000 Russian shells per day, provides an indication of this.16 https://www.inforadio.de/rubriken/interviews/2022/07/11/ralph-thiele-militaer-offensive-ukraine-krieg-russland-ausgang.html

It is emphasised here that for some large-scale equipment the currently available share would only be 40%, while for other equipment, such as support vehicles for logistics and medical services, the available share is given as over 80%. The latter can be considered optimal with respect to usual ratios in functioning maintenance logistics.

However, management methods for reducing life cycle costs aim precisely at creating the conditions for ensuring optimal availability in the utilisation phase already at the procurement stage.

The fact that the implementation of LCC methods is very hesitant is also evident from the publications of the Bundeswehr University of Applied Sciences in Munich, which could thus act as a „think tank“ for business efficiency in the Bundeswehr. The only working paper on this topic published there is „Market-side investigation of the application progress of life cycle cost management in the defence and security industry“ (Eßig, 2021). However, the study deals with LCC management in industry and presents survey results among suppliers. The logical approach, however, would be – in line with the approach described in the USA – to start with concepts for the user, i.e. the Bundeswehr, for the purpose of resulting specifications for the industry.

3.2 Costs of the exercise operation

Military mobility and civil infrastructure

Most of the time, military training areas do not exist in the vicinity of larger military stationing sites, but in rather remote regions. In addition, the German Federal Armed Forces are also increasingly exercising in Eastern Europe on a rotational basis. This also results in increased demands on the infrastructure of the German railways and the German trunk road network. Due to the lack of transparency, it is not possible to estimate what proportion of the BMDV’s planning in accordance with the Federal Transport Infrastructure Plan is due to military requirements. However, it is worth mentioning:

Since 2016, there has been the EU programme „Connnecting Europe Facility“. This is an EU programme that is being used to expand the rail infrastructure for fast military transports throughout Europe. Among other things, there is the expansion of the so-called „740-metre network“. This refers to a specific network to be used for military purposes, on which goods trains with a length of 740 metres can run loaded with tanks and other military equipment.18For comparison: ICE stations have a track length of approx. 440 metres Furthermore, special requirements include a complete electrification of the DB network as well as tunnel profiles adapted to tank transports.19 https://umwelt-militaer.org/hochruestung-auch-im-bereich-schiene/

Also within the framework of the EU, a programme was set up as the PESCO project „Military Mobility“, for which the EU Commission in 2017 estimated 6.5 billion euros as a multi-year financial framework from 2021 to 2027, but which was later reduced to two billion euros.20https://www.imi-online.de/2020/02/21/kriegslogistik-und-militaerische-mobilitaet/ In November 2022, the EU Commission presented an „Action Plan Military Mobility 2.0“.21https://defence-industry-space.ec.europa.eu/action-plan-military-mobility-20_en This aims to accelerate the earlier planning and implement it by 2026. It states in section 3.1 that the focus is on investments in „dual-use“ infrastructure. This means that in addition to some purely military investments, such as regionally distributed depots for fuel supply, the civilian infrastructure is to be expanded in a targeted manner according to military requirements with support from the EU budget.

Deutsche Bahn concluded a contract with the Bundeswehr in 2019 for more than 1,300 annual military transports, including cross-border ones. This was accompanied by the procurement of 300 additional wagons by DB.22https://www.imi-online.de/download/IMI-Analyse2019-1-Bahn.pdf It is also important to note the considerable increase in the Bundeswehr’s total civilian and military vehicle fleet, resulting in a corresponding increase in the use of civilian transport infrastructure (see Annex A.3: Land mobility of the Bundeswehr).

Use of airspace

The proportionally largest cost and thus environmental impact of the military comes from air traffic. This extends to:

- Flying hours in fighter jet training zones, including low-level flights and military radio stations to simulate enemy radar.

- aerial refuelling of fighter jets with transport aircraft

- civil and military transport flights to supply globally existing military bases and training areas

- military transport flights for land vehicles and helicopters to training areas, e.g. from Germany to Eastern Europe.

Environmental pollution is caused by greenhouse gases, aircraft noise, paraffin emissions and pollutant discharges at military bases where fighter jets are stationed (see Chapter 5). Regarding the costs of flight operations, see Chapter 6.1 for an example of the F-35 fighter jet.

Presence on the seven seas

The entire surface and submarine fleet of the Bundeswehr requires considerable land areas for docking and logistical supply. As the German Navy is geared towards an increasingly global presence23See also the exemplary presentation of the Frigate 126 project in Chap. 6.3, increased logistics costs also arise that can no longer be transparently tracked, as is the case with landings at US Navy military bases in the Pacific.24See also Chap. 5.1 regarding GHG emissions according to Scope 3 (indirect emissions).

3.3 Decommissioning and disposal

A major problem for the life cycle assessment of defence equipment is that there are hardly any defined disposal concepts. Typical is the mothballing of large equipment, as is also practised in the civilian sector, especially in the air dimension, when equipment is temporarily taken out of service.

The recycling after the end of use is unclear, especially in the case of battle tanks. The Leopard 1 was built in a number of 4,700 units from 1964 to 1984.25https://de.wikipedia.org/wiki/Leopard_1 In the German Armed Forces, the last units were decommissioned at the end of 2003 and thus replaced by the successor Leopard 2.

In principle, according to the Treaty on Conventional Armed Forces in Europe 26https://de.wikipedia.org/wiki/Vertrag_%C3%BCber_Konventionelle_Streitkr%C3%A4fte_in_Europa with the partial demilitarisation stipulated therein, old tanks are also scrapped. This is done in Rockensußra, Thuringia, in Europe’s only NATO-certified tank scrapping facility.

Fig. 3-5: Tank scrapping plant in Rockensußra

Source: Google Earth

3.4 Conclusion

Systematic underestimation of life cycle costs: Despite existing approaches on several levels and various LCC tools, concepts and tools for recording life cycle costs are at best used for accounting purposes and are hardly relevant for decision-making.

No consideration of environmental aspects: Although in principle provided for in the service regulations and also in the law to accelerate procurement measures, there are no concrete specifications on the extent to which environmental aspects are taken into account in procurement processes.

No transparency in maintenance: In the reports on the material readiness of the Bundeswehr, which are temporarily presented to the public, the problems in logistics and the management of maintenance are hinted at, but the causes and consequences are not examined in detail. For years, however, this topic was anchored in the public debate with the narrative of Bundeswehr underfunding.

Rising costs due to exercise operations: Especially in military air operations, rising operating costs are to be expected due to the increase in foreign deployments.

Operational use of the civilian transport infrastructure: The use of the civilian road and rail network is associated with expansion and maintenance costs, the amount of which, however, is not presented in the EU project „Military Mobility“.

No defined disposal concepts: In view of the only selective disposal processes, it remains unclear what civilian „end of life“ concepts exist for defence equipment in the sense of a circular economy.

References

Estevan, Helena; Schaefer, Bettina. 2017

Life Cycle Costing – State of the art report | Hrsg: Ecoinstitut SCCL

https://sppregions.eu/fileadmin/user_upload/Life_Cycle_Costing_SoA_Report.pdf

Eßig, Michael u.a. 2021

Marktseitige Untersuchung des Anwendungsfortschrittes des Lebenszykluskostenmanagements in der Verteid gungs- und Sicherheitsindustrie | Hrsg.: Universität der Bundeswehr München, Arbeitsgebiet Beschaffung

https://www.unibw.de/beschaffung/arbeitspapier-23-marktseitige-untersuchung-des-anwendungsfortschrittes-des-lebenszykluskostenmanagements-in-der-verteidigungs-und-sicherheitsindustrie.pdf/download

GAO US Government Accountability Office. 2020

Cost Estimating and Assessment Guide – Best Practices for Developing and Managing Program Costs

https://www.gao.gov/assets/gao-20-195g.pdf

Gössling, Stefan; Kees, Jessica; Litman, Todd. 2022

The lifetime cost of driving a car

https://www.sciencedirect.com/science/article/pii/S0921800921003943

Ministry of Defence (UK). 1992

Planning for Lifecycle Costs

https://www.nao.org.uk/pubsarchive/wp-content/uploads/sites/14/2018/11/Ministry-of-Defence-Planning-for-Lifecycle-Costs.pdf

Ministry of Defence (Australien). 1998

Life-cycle Costing in the Department of Defence

https://www.anao.gov.au/sites/default/files/anao_report_1997-98_43.pdf